Ship-side valves refer to the valves that are connected to the hull without having anything in between is called Ship-side valve.

During dry dock the valves are overhauled by the dry dock workshop personals, where-as the job of the marine engineers is to overhaul internal valves.

why ship-side valves are important ?

In ship everything that has been installed have some purpose, moreover Ship-side valves are inspected and check by Classification society.

Ship side valve must be non-return type. Screw done non--return valves are used as ship side valves because it help in preventing the flooding of the vessel in-case of fracture or break with discharge submerged, they also allow isolation to prevent so.

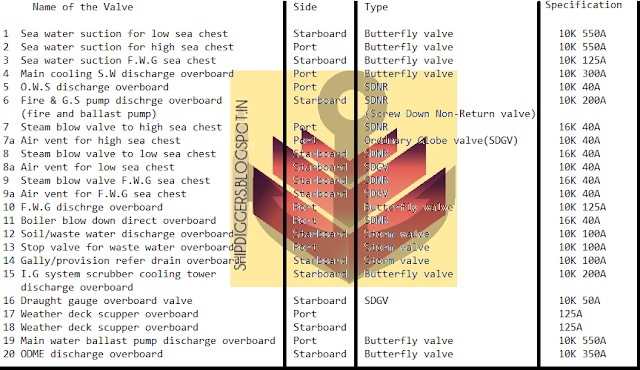

Name of the Valve Side Type Specification

1 Sea water suction for low sea chest Starboard Butterfly valve 10K 550A

2 Sea water suction for high sea chest Port Butterfly valve 10K 550A

3 Sea water suction F.W.G sea chest Starboard Butterfly valve 10K 125A

4 Main cooling S.W discharge overboard Port Butterfly valve 10K 300A

5 O.W.S discharge overboard Port SDNR 10K 40A

6 Fire & G.S pump discharge overboard Starboard SDNR 10K 200A

(fire and ballast pump) (Screw Down Non-Return valve)

7 Steam blow valve to high sea chest Port SDNR 16K 40A

7a Air vent for high sea chest Port Ordinary Globe valve(SDGV) 10K 40A

8 Steam blow valve to low sea chest Starboard SDNR 16K 40A

8a Air vent for low sea chest Starboard SDGV 10K 40A

9 Steam blow valve F.W.G sea chest Starboard SDNR 16K 40A

9a Air vent for F.W.G sea chest Starboard SDGV 10K 40A

10 F.W.G discharge overboard Port Butterfly valve 10K 125A

11 Boiler blow down direct overboard Port SDNR 16K 40A

12 Soil/waste water discharge overboard Starboard Storm valve 10K 100A

13 Stop valve for waste water overboard Port Storm valve 10K 100A

14 Gally/provision refer drain overboard Starboard Storm valve 10K 100A

15 I.G system scrubber cooling tower Starboard Butterfly valve 10K 200A

discharge overboard

16 Draught gauge overboard valve Starboard SDGV 10K 50A

17 Weather deck scupper overboard Port 125A

18 Weather deck scupper overboard Starboard 125A

19 Main water ballast pump discharge overboard Port Butterfly valve 10K 550A

20 ODME discharge overboard Starboard Butterfly valve 10K 350A

What does K and A stand for in specifications?

K : is the pressure.

A : is the Nominal diameter of the pipeline.

Example: 20K 50A

This means 20 kg/cm² is the pressure that can be easily handled by the valve.

where as 50 is the Nominal Diameter of the pipeline that can be fixed with the valve.

|

| Copyright of Shipdiggers. |

why ship-side valves are important ?

In ship everything that has been installed have some purpose, moreover Ship-side valves are inspected and check by Classification society.

- Dry Dock Workshop after repairing or installing new valve, generally give 5 years guarantee for these valves.

- However if the valves that get damaged within the guarantee period, the expense of delay in time and diver* cost is given by the dry dock workshop.

Ship side valve must be non-return type. Screw done non--return valves are used as ship side valves because it help in preventing the flooding of the vessel in-case of fracture or break with discharge submerged, they also allow isolation to prevent so.

| |||

| Under Copyright of Shipdiggers. Table credit: Arpit Singh |

1 Sea water suction for low sea chest Starboard Butterfly valve 10K 550A

2 Sea water suction for high sea chest Port Butterfly valve 10K 550A

3 Sea water suction F.W.G sea chest Starboard Butterfly valve 10K 125A

4 Main cooling S.W discharge overboard Port Butterfly valve 10K 300A

5 O.W.S discharge overboard Port SDNR 10K 40A

6 Fire & G.S pump discharge overboard Starboard SDNR 10K 200A

(fire and ballast pump) (Screw Down Non-Return valve)

7 Steam blow valve to high sea chest Port SDNR 16K 40A

7a Air vent for high sea chest Port Ordinary Globe valve(SDGV) 10K 40A

8 Steam blow valve to low sea chest Starboard SDNR 16K 40A

8a Air vent for low sea chest Starboard SDGV 10K 40A

9 Steam blow valve F.W.G sea chest Starboard SDNR 16K 40A

9a Air vent for F.W.G sea chest Starboard SDGV 10K 40A

10 F.W.G discharge overboard Port Butterfly valve 10K 125A

11 Boiler blow down direct overboard Port SDNR 16K 40A

12 Soil/waste water discharge overboard Starboard Storm valve 10K 100A

13 Stop valve for waste water overboard Port Storm valve 10K 100A

14 Gally/provision refer drain overboard Starboard Storm valve 10K 100A

15 I.G system scrubber cooling tower Starboard Butterfly valve 10K 200A

discharge overboard

16 Draught gauge overboard valve Starboard SDGV 10K 50A

17 Weather deck scupper overboard Port 125A

18 Weather deck scupper overboard Starboard 125A

19 Main water ballast pump discharge overboard Port Butterfly valve 10K 550A

20 ODME discharge overboard Starboard Butterfly valve 10K 350A

What does K and A stand for in specifications?

K : is the pressure.

A : is the Nominal diameter of the pipeline.

Example: 20K 50A

This means 20 kg/cm² is the pressure that can be easily handled by the valve.

where as 50 is the Nominal Diameter of the pipeline that can be fixed with the valve.